The engine analysis laboratory is equipped with several facilities:

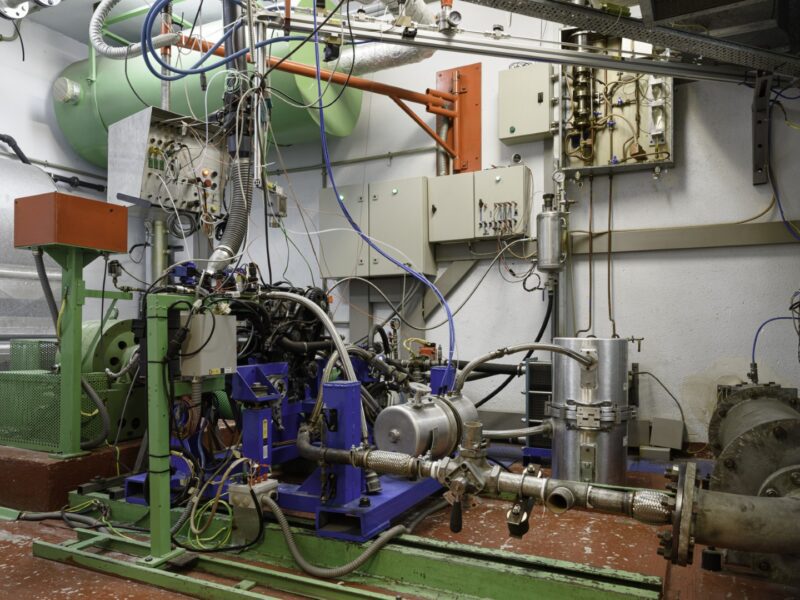

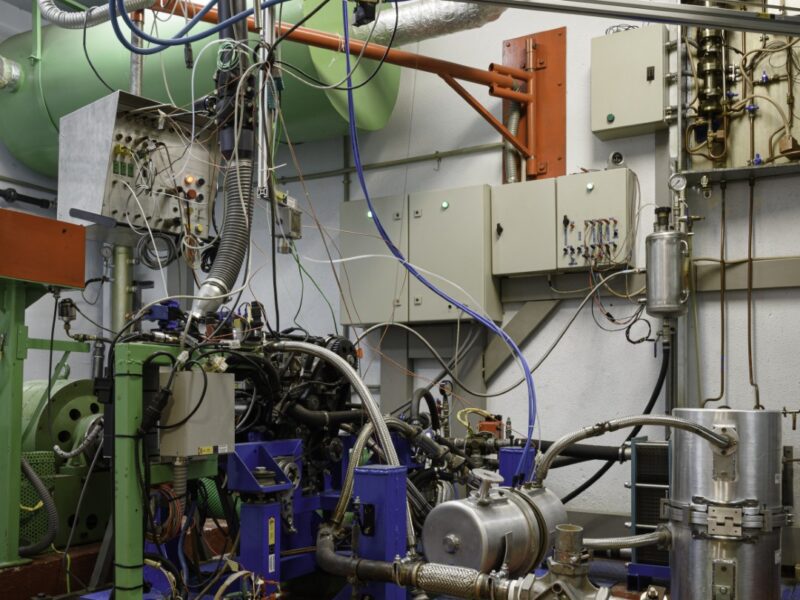

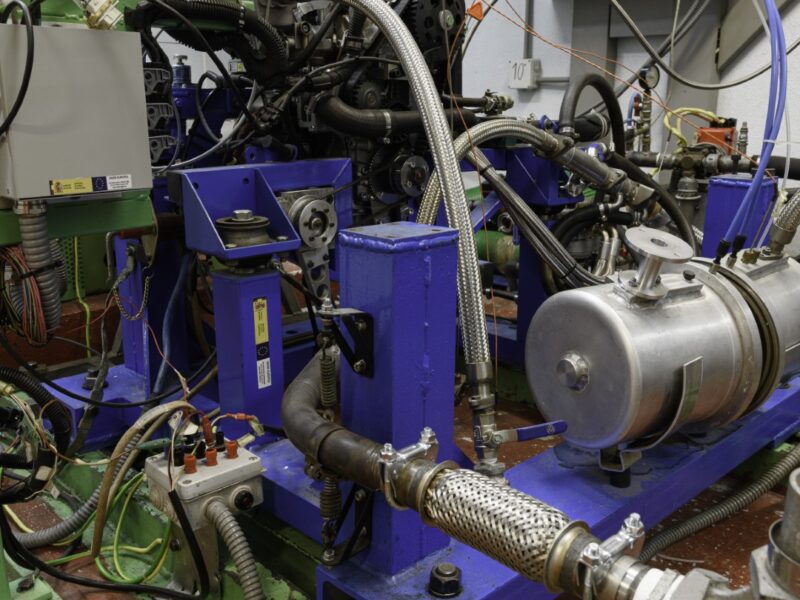

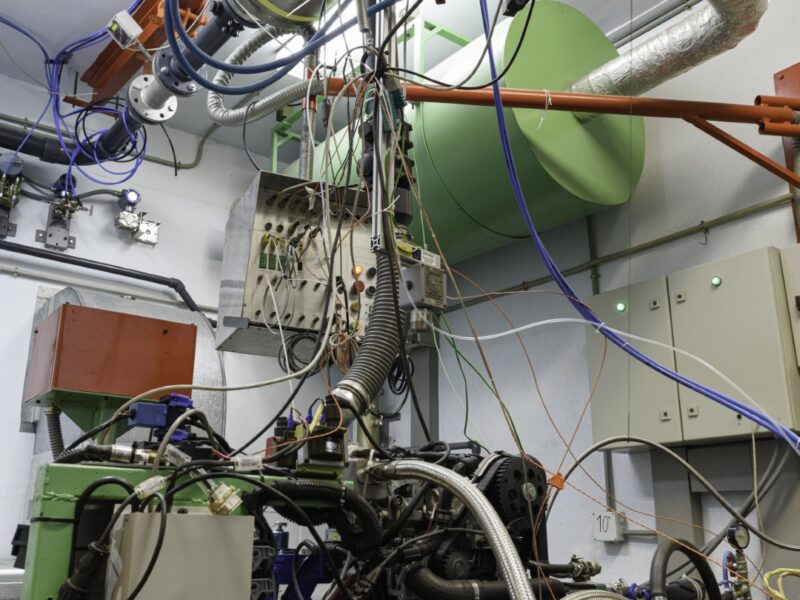

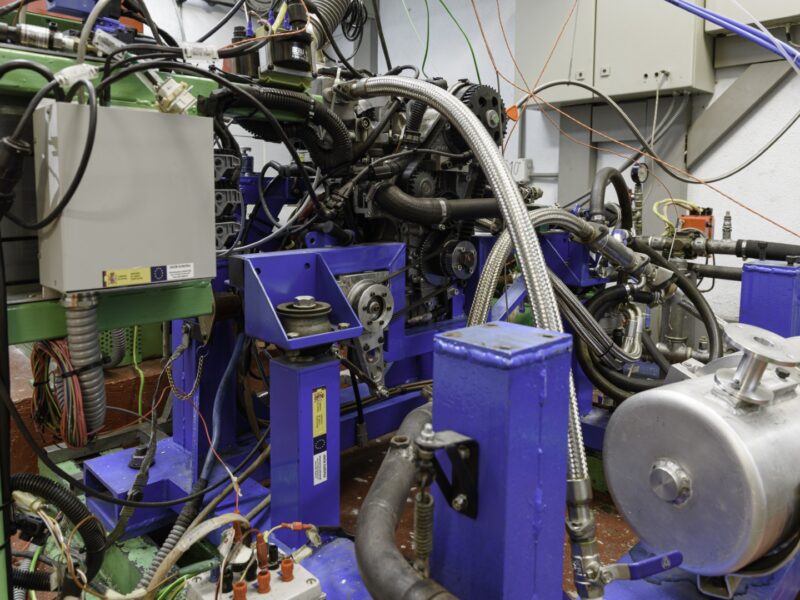

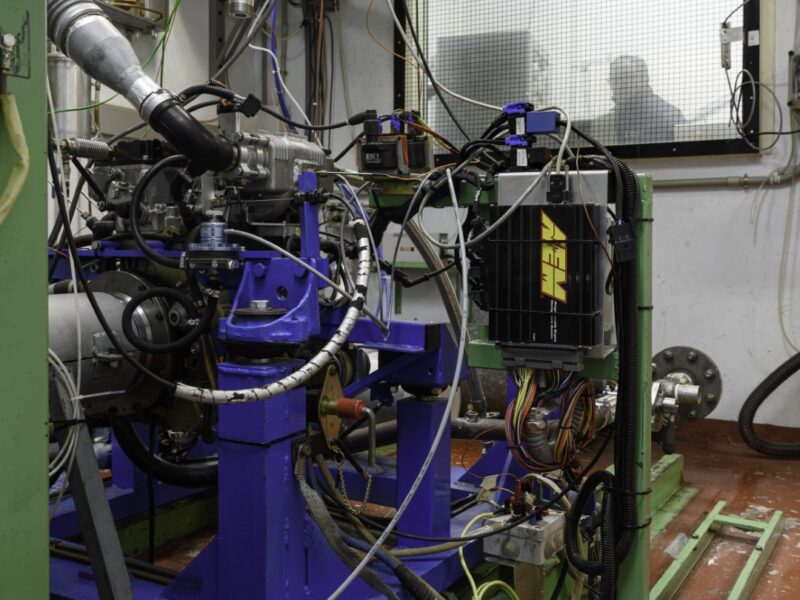

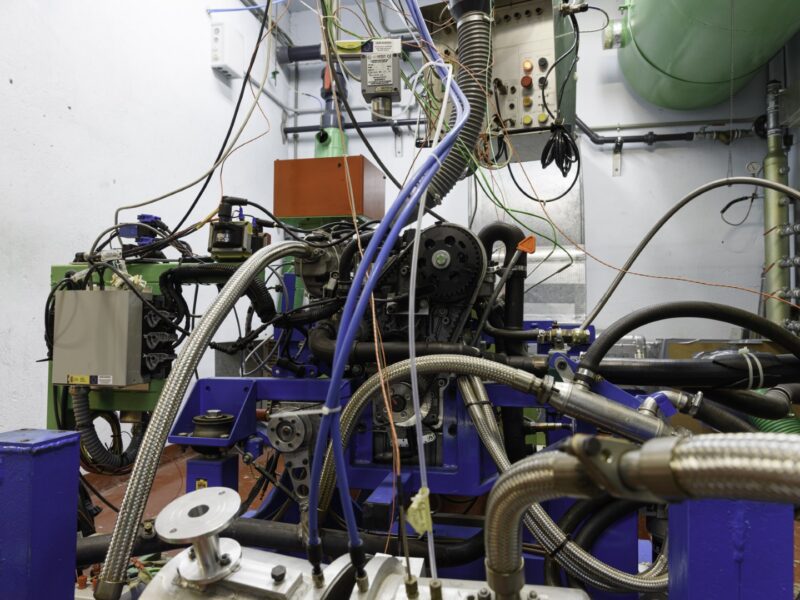

1. Engine test bench

It is a fully equipped and operational dynamometric brake test bench for MCIA testing. The necessary regulation and control elements and systems are available to operate the engine under conditions similar to its final installation in a vehicle or fixed setup. A pollutant and CO2 emissions measurement system is available, compliant with European regulations. Any engine with a maximum power of up to 150 kW (~200 HP) and a maximum rotational speed of 9,000 rpm can be mounted.

It allows the following tasks to be performed:

- Engine testing: Determination of basic performance parameters such as torque, power, and specific fuel consumption. Assessment of thermal behavior, including overheating, thermal shock, and energy balance. Maintenance and fatigue analysis, including durability, failure prediction, and fouling.

- Testing of alternative fuels: Gasoline and alcohol blends, natural gas, low-quality gases, hydrogen, biogases, etc.

- Pollutant measurement: Nitrogen oxides (CLD), hydrocarbons (FID), carbon monoxide, and carbon dioxide (NDIR).

2. Steady flow bench

Used for evaluating the design of engine valves, intake and exhaust manifolds, filters, duct joints, etc.

3. Experimental CO2 capture system coupled to the engine test bench

A laboratory-scale TSA-based CO2 capture system has been designed and built.

It allows CO2 capture tests to be performed using TSA on combustion gases from an engine installed on the engine test bench.