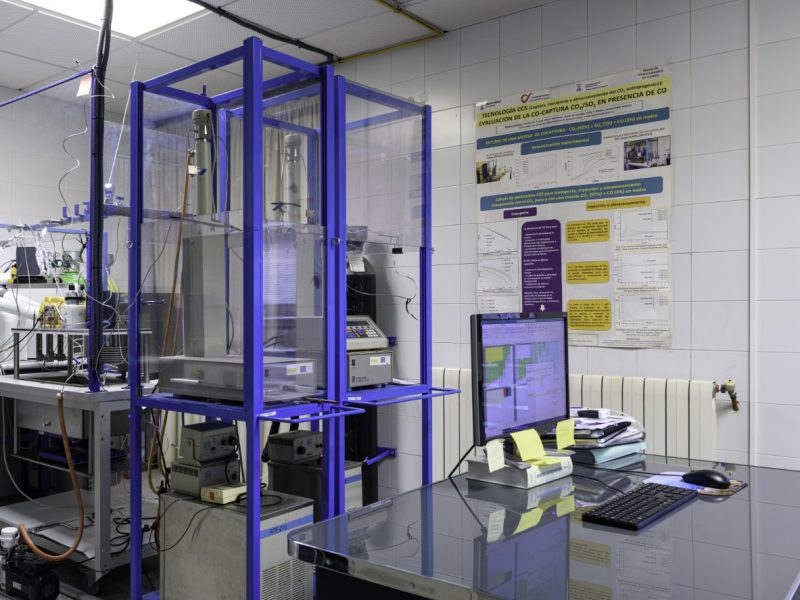

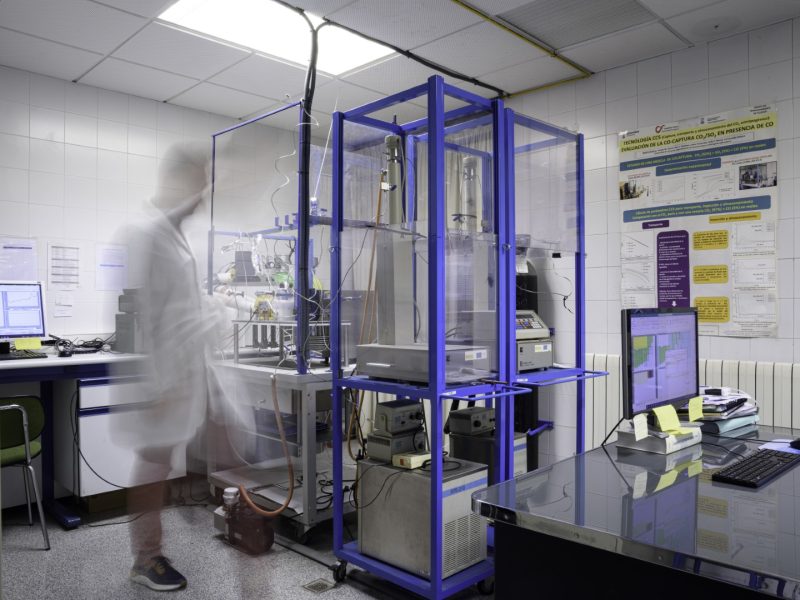

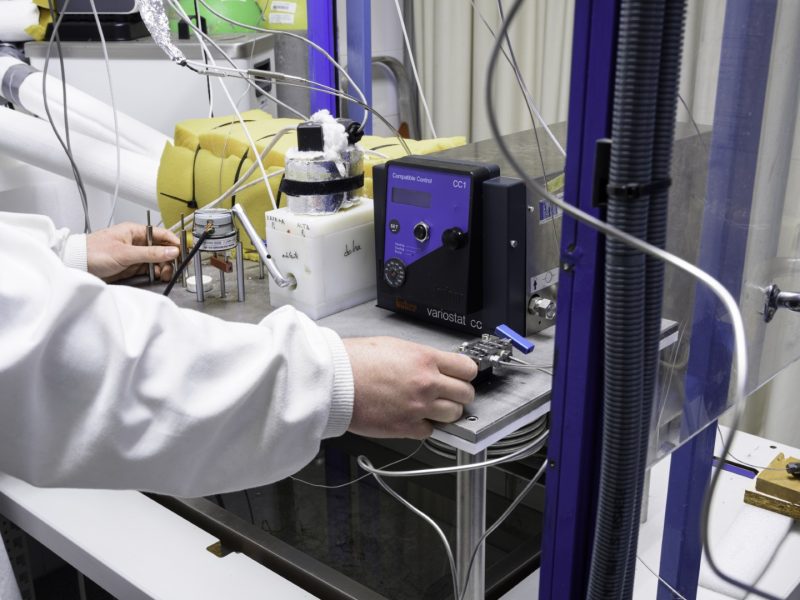

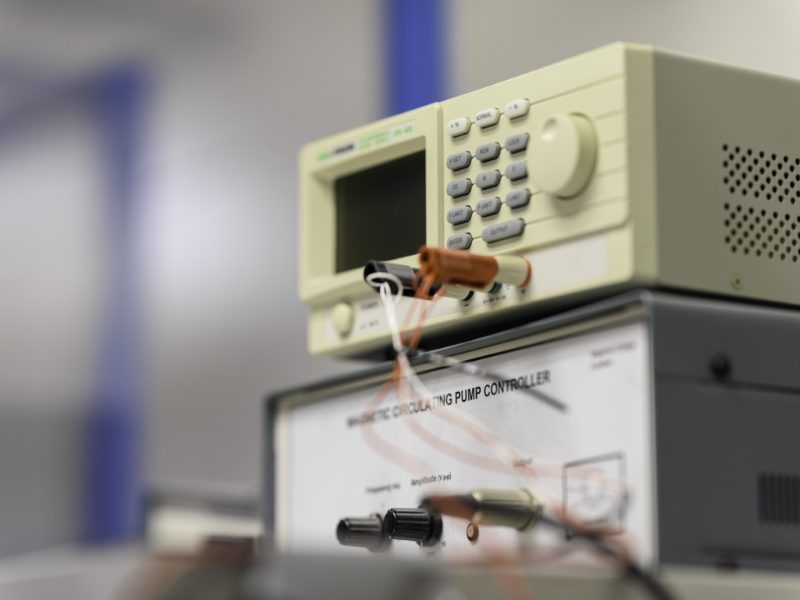

The thermodynamic characterization facilities consist of two laboratories designed for working with pure compounds and mixtures in gas, liquid, or compressed phases. Both laboratories have been adapted for the safe handling of toxic and hazardous substances and are equipped with comprehensive safety measures. All experimental apparatuses are enclosed in bulletproof polycarbonate panels, and additional safety systems include fume hoods, gas masks, supplied-air hoods, and gas detectors with sensors calibrated for all relevant pollutants.

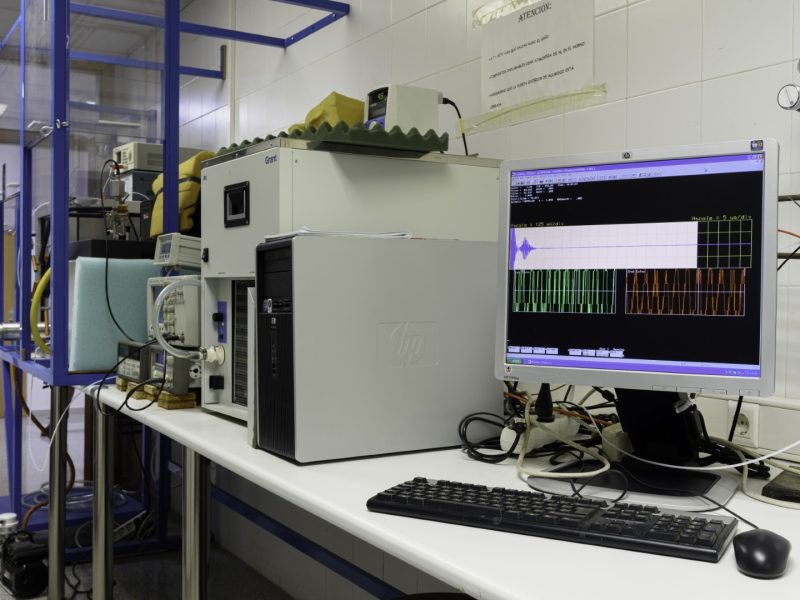

High-Pressure Pressure-Density-Temperature and Vapor–Liquid Equilibrium (PdT–VLE) Laboratory

- Operating ranges: P ≤ 70 MPa and 263 K ≤ T ≤ 423 K

- Measurement uncertainties:

- Pressure: u(P) = 0.015 MPa for P < 6 MPa; u(P) = 0.0175 MPa for 6 MPa ≤ P ≤ 70 MPa

- Temperature: u(T) = 0.006 K

- Composition: u(x) = 0.0002

- Density: average u(d) = 0.4 kg/m³

The data acquisition system enables quasi-continuous measurement along subcritical, critical, and supercritical regions (up to 6000 P–d–T data points per isotherm, typically reduced to ~1000 for practical handling). This allows for the precise determination of VLE boundaries, dew and bubble pressures, and phase densities, with average uncertainties of 0.02 MPa and 1.0 kg/m³, respectively.

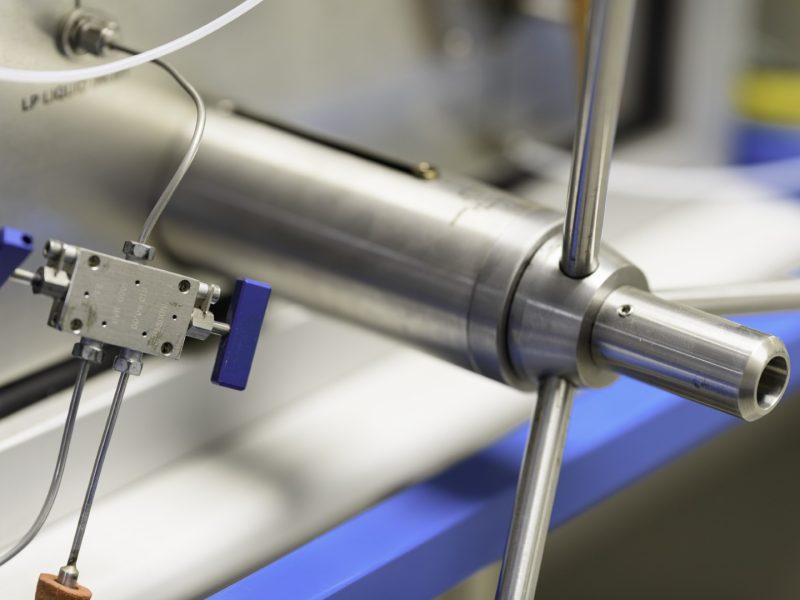

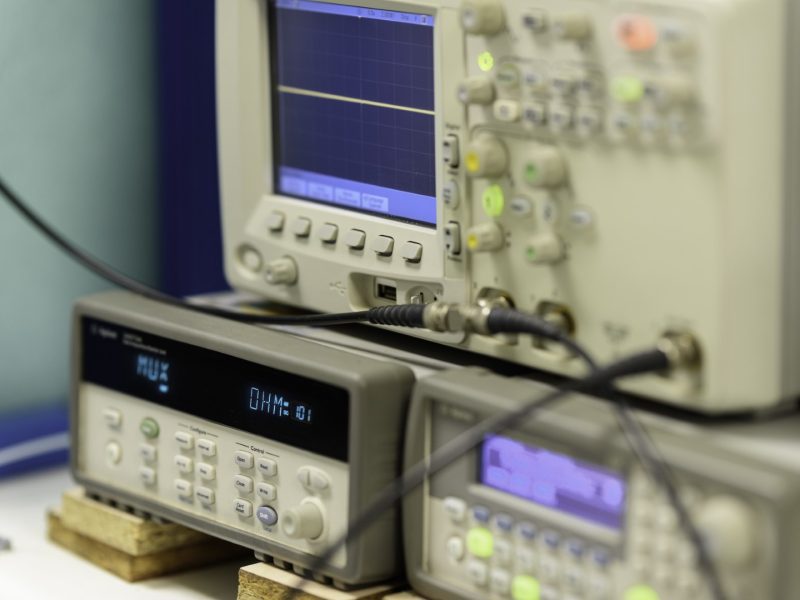

High-Pressure Pressure–Speed of Sound–Temperature (PcT) Laboratory

- Operating ranges: P ≤ 200 MPa and 253 K ≤ T ≤ 473 K

- Measurement uncertainties:

- Pressure: u(P) = 0.02 MPa

- Temperature: u(T) = 0.015 K

- Composition: u(x) = 0.0002

- Speed of sound: average u(c) = 0.06%

This facility, originally designed for measuring the speed of sound in liquids, has been successfully adapted and commissioned by the research team for use with compressed gases.

Software Tools

To model experimental data using equations of state, the laboratories are equipped with the following software: REFPROP 10.0, TREND 5.0, and VLXE.